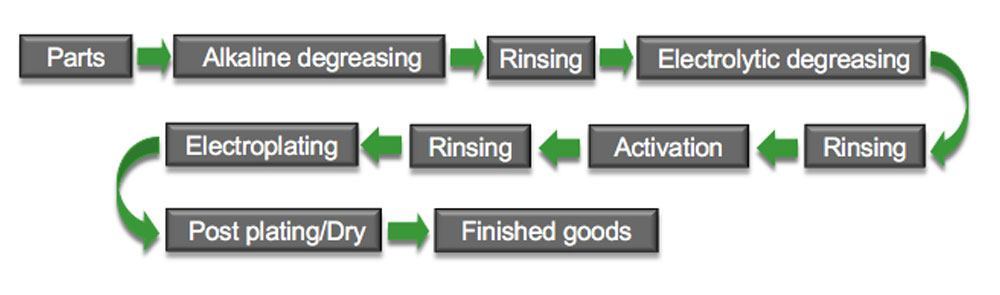

We are pleased to announce opening of state of the art newly constructed plating facility in Tong Xiang.

Adding metal plating to our product portfolio further plays an important role in our strategic road map of bringing value to our customers in offering end-to-end interconnect solutions.

The recent investment in this facility includes state of the art plating equipment

- Barrel Plating

- Rack Plating

- Reel to Reel

As well as cleaning, tumbling and drying equipment inclusive:

- Ultrasonic Cleaning

- Acid Etch

- Pickling surface treatment

- Sand Blasting

Set up in accordance with best practices of meeting environmental legislation and providing superior quality plated parts.

Excellent engineering, material science and management teams are in place to innovate and solve customer specific challenges with tremendous experience and knowledge of materials and plating finishes support critical solutions. The team is on hand to provide product knowledge and advice in selecting the most appropriate plating finish for a particular application.

Plating upon connectors & components with base metals of:

- Aluminium

- Zinc

- Mild Steel

- Brass

- Bronze

- Beryllium Copper

- Zinc Alloy

With Plating finishes of:

- Zinc

- Nickel Chromium

- Zinc Cobalt

- Nickel

- Tin

- Silver

- Black Zinc

- Black Silver

- Gold

A full and diverse range of application methods are offered including jigged parts, rotating and vibrating barreling parts, as well as selective surface plating.

Our experienced quality team has access to the latest state-of-the-art analytical technology including x-ray fluorescence equipment for the determination of plated metal thickness and zinc alloy analysis, an atomic absorption spectrophotometer. Our plating facility exceeds or meets the most stringent international standards such as Mil, ASTM & AMS.

Line 1: Reel to Reel

Application

- Product: Electronic connectors ( connector terminal) Netcom, SIMcard, RJ, Power pin.

- Substrate: Cu, Iron,stainless steel.

- Deposition layer :Cu , Ni , Sn / Au

- Tank size: ( W25*H30 cm)

- Max. capacity: 6KKpcs/24hrs

- Feature:Fulfill both full &selected Au plating feasibility

Line 2: Barrel Plating

Application

- Product: Electronic connectors ( connector terminal D-SUB shell,HDMI latch, screw and nuts, which can be applied on the small parts (non- cosmetic parts).

- Substrate : Cu, Iron

- Deposition layer : Cu , Ni , Sn ( Matt / Bright )

- Max. capacity: 5,000Kg/24hrs

Line 3: Rack Plating

Application

- Product:Big parts which can’t be done over the barrel plating, cosmetic requirement feasibility.

- Substrate: Cu, Iron, Zinc-alloy, aluminium alloy

- Deposition layer : Cu , Ni , Cr, passivation treatment

- Max. capacity: 150Kpcs/24hrs

- Feature: combo design for both Zinc

- Alloys & Aluminum Alloys

- Reserve the capability for the cosmetic part

The Range of Electroplating License Approved:

- Gold plating (Nickel, Tin, Pd/Ni, etc.)

- Reel to reel

- Barrel

- Silver plating (Nickel, Tin, Pd/Ni, etc.)

- Reel to reel

- ABS Plastic (Nickel,Chrome3+, etc.)

- Rack

- Zinc alloy (Nickel, Chrome3+, etc.)

- Rack

- Aluminum Anodizing

- Rack